Protect stock. Prevent spoilage. Sleep well.

With BenchMarker Cloud for Cold Storage, you’ll know instantly if temperatures drift or unwanted gases rise, in any part of the cool store — saving thousands in lost inventory and giving you simple compliance reporting.

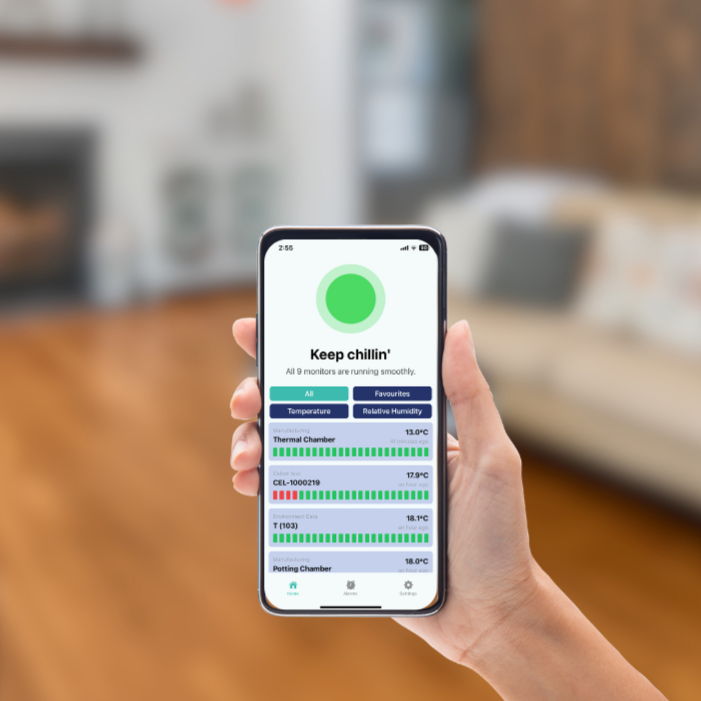

Check the App anywhere, anytime. Or just let it tell you when to look.

The Challenge:

Produce spoiling is costly — and all too often goes unnoticed until it’s too late.

Not having all the measurement data you want - from anywhere, any time - can result in causes, leaks and equipment issues go unnoticed.

Moving stock into storage too early, cool rooms with varying leaks, equipment not actually working the way you want can all cause headaches and storage losses for managers and business owners.

Collecting data for compliance and reporting causes stress and takes up staff time. Inaccuracies can be costly.

Traditional gas sampling methods are expensive and slow, and waiting days for results is not fast enough. Temperature sensors and probes wired into walls are easily damaged and difficult to fix, and often not where they need to be.

The Solution:

BenchMarker Cloud keeps watch 24/7 so you can tune controls and have peace of mind all is well.

Placing sensors anywhere from ground up (even throughout densely packed fruit bins) sources accurate and rapid measurements that answer the best produce movement and storage questions. Managers can derive answers to storage questions hourly, and day-by-day tune operations.

Reliable, standards-based measurements provide audit and compliance reports.

Robust, accurate, wireless sensors measure temperature (ambient and fruit probes), humidity, carbon dioxide and ethylene.

Proven in the toughest of environments - in refrigerated containers, 8000-bin cool stores and larger, and at ultra-low temperatures deep in large buildings, stores, freezers and fridges.

Robust monitoring of spaces, produce and specialty items.

Anywhere.

BenchMarker Cloud is ideal for improving the quality of control of cooled spaces in fruit coolstores, supermarkets, food processors, medical facilities, science labs, vet clinics, offices, museums, art galleries, hop kilns, orchards and any kind of specialty storage in buildings and containers.

Ambient Temperature

Relative Humidity

Fruit Temperature

Carbon Dioxide

Ethylene

Volatile Organic Compounds

Movement

Air Pressure Differentials

24/7 Monitoring

-

Fridge, freezer and stock. Celsor has a variety of types for measuring temperature (ambient and fruit/meat), humidity, carbon dioxide and ethylene, pressure differential, and remote I/O - anywhere, for 6+ years on a battery.

Instant Alerts

-

Be notified when temperatures, humidity, carbon dioxide or ethylene levels drift outside safe ranges.

Automated Logs

-

Permanent, secure records with notes from users.

All monitoring in one view

-

Accessible anywhere — browser or mobile app with powerful graphics and analysis. All sites in one view, with floor plans.

Predictive Maintenance

-

BenchMarker will spot patterns like compressors failing. Find out before a breakdown – fix before failure.

A technician can view the historical patterns and remotely diagnose, which means showing up with the right parts first time for a single-visit fix.

Easy Retrofit

-

Place sensors wherever they are needed and affixed by screwing to a wall, cable tying or by using magnetic strips.

Achieve reliable data flows from anywhere in your building or cold storage facility - without Wi-Fi or cellular.

Trusted by Earth Sciences NZ to Protect Antarctic Ice Samples

When you are responsible for the storage of New Zealand’s Antarctic ice core samples, the last thing you want to be greeted by on Monday morning is an expensive puddle on the floor.

The Facility Management Team of Earth Sciences NZ (formerly GNS Science) searched the world for a monitoring solution that would meet their rigorous demands for Antarctic ice sample storage.

There was a long list of requirements: no drilling of holes in the walls for temperature probe cables, and no data loggers that required manual downloads. The solution needed to be wireless, battery-operated with automatic and continuous communications, in extremely cold conditions. But communication signals would have to get through multiple layers of metal walls — an impossibility for wireless technologies like Wi-Fi or cellular.

Added to that, the information needed to be available to multiple people, on one view, from three different sites around the country, without touching any of their local area networks.

And to top it off, not only did the data security need to meet the highest global standards, the data needed to not be with the device itself, but permanently stored against the name of a measurement point, so devices could be swapped out for battery replacement without data loss.

Celsor - temperature sensor

BenchMarker Cloud by Vention Lab was the ideal solution.

A single external LPWAN gateway was mounted on the roof of the facility to communicate with all the sensing devices, wherever they were placed throughout the many buildings, including inside refrigerated containers. A gateway uses very little power, which is supplied over Ethernet cable, yet the signal covers many kilometres and penetrates deeply into concrete and steel structures.

The wireless ‘Celsor’ devices for measuring temperature easily communicate from the difficult environments. The device has a battery that can handle the -40C and which doesn’t need replacing more than once every 4 or 5 years (the battery normally lasts longer in less harsh conditions). The BenchMarker Cloud servers continuously check that all sensors are in communication. The data is sent every two hours in 15 min bundles, and if there is an out-of-condition state detected at the monitor the alert is immediate to a rostered group of users.

No one has to keep an eye on anything or record any temperatures - the system does all recording and monitoring, notifies any problem immediately, and the auto self-checking means staff are notified should a Celsor be offline for any reason and unable to deliver alerts.

The BenchMarker Cloud system meets OWASP Application Security Verification Standard 4.0 — a recognised global benchmark for cloud-application security and which assures operational and customer data is handled according to the same principles as applied by banks, utilities, and government agencies.

Achieved: accurate, robust, multi- user secure access, auditable, long-life and reliable monitoring and alerts.

(And the Facility Management Team now gets to enjoy their weekends with no stressful thoughts of unwanted puddles!)

BenchMarker - Cold Storage App

BenchMarker Cloud sensors are compact and quick to install, with no disruption to daily operations. Your team gets proactive alerts and automated reporting straight away.

Quick to set up. Easy to run.

FAQs

-

Yes — the dashboard lets you view all units at once, across multiple sites (nationally and internationally). All devices in your account show on a handy App where you can see an overview and drill down into deeper detail as you wish.

One Celsor device per monitoring point. -

No — BenchMarker Cloud automates the process and generates reports for audits.

-

BenchMarker Cloud self-checks continuously, and can alert if any part of it is down for any reason, e.g. power outage at the comms gateway.

The sensors continue collecting data through power outages, and when the power returns to the comms gateway the sensors backfill the information to the online portal.

We often provide our clients with a redundant system so they can continue being alerted to problems even if power or comms fail locally.Vention Lab’s Cloud servers are reliable, and have never lost any customer data.

-

The Vention Lab sensors are built for 25+ years lifetime. The long-life battery lasts 6-10 years and optionally 12-20 years. Battery longevity depends on communication frequency chosen. They may be replaced by return to factory or by a locally trained technician.

-

All of the devices are designed, manufactured and supported by a capable team in New Zealand. They are designed for the globe, and will work anywhere.

BenchMarker Cloud: for one view across all buildings…

Water usage

•

Fridge/Freezer/Chiller monitoring

•

Power usage/load-shedding

•

Auto-door performance

•

Heating, Ventilation, and Air Conditioning Monitoring & Control

•

Room Occupancy/Air Quality

•

Bottled gas monitoring

•

Metered gas monitoring

•

Cool storage gases (CO2 and Ethylene)

Water usage • Fridge/Freezer/Chiller monitoring • Power usage/load-shedding • Auto-door performance • Heating, Ventilation, and Air Conditioning Monitoring & Control • Room Occupancy/Air Quality • Bottled gas monitoring • Metered gas monitoring • Cool storage gases (CO2 and Ethylene)

Simple. Smart. Supported.

Use BenchMarker Cloud to:

measure and record temperature, relative humidity, carbon dioxide, ethylene, and pressure differentials in air ducts

alert to out of condition states immediately by SMS and email

detect inefficient compressor operation - fix before failure

automate audit trails and reporting

-

High-frequency, precise measurements stored and analysed in the Cloud

Installs anywhere monitoring is needed - no wiring, no Wi-Fi and no local area network needed

Simple and quick retrofit.

Automatic detection of deviations and refrigeration machinery behaviour analysis.

Persistent data for evidence, compliance, and root-cause analysis

History of alarms permanently recorded, with user notes

Notification to rosters

User permissions defined by Admin: View, Edit, Admin.

User configurable settings; two highs and two lows with recovery period settings for alerts

Notifications by SMS and/or email

Alarm history

Change logs to alert parameters

Data flows directly to the cloud, no central processing hub required in the building

All buildings in one online view

Geospatial view of measurement points with floor plans

Automated audit reporting

Permanent records, user notes recorded, downloadable CSV files

Daily/weekly/monthly reports

Data stays with the named measurement point, not the device, so devices may be swapped out without loss of data.

Online calibration tools for self-calibration

External calibration services available

System self-checks that devices are communicating

Global grade engineering - the devices work for decades without maintenance

Other edge devices (e.g. for water usage, power usage, gas usage, HVAC performance information) appear in the same dashboard.

-

Name: Celsor - Variants:

Temperature

Temperature + Humidity

Temperature + Humidity + CO2

Temperature + Humidity + Ethylene

Fruit probe - kiwifruit/apple

Pressure differential

Remote I/O

Accuracy:

Temperature +/ 0.25C

Humidity +/ 0.3 (typical) from -40C to 125C

CO2: ranges 10,000 and 30,000 ppm (1% and 3%) at 10 ppm resolution

Ethylene: ranges 10,000 and 40,000 ppm (1% and 4%) at 1 ppb resolution

Wireless range: approx 2km - 15km depending on terrain

Antenna: enclosed, internal LPWAN

Wireless comms technology: LoRaWAN 1.0.2 or CAT-M1

LED: Red/Green LED to indicate installed and connection status

Monitoring rate: 5 sec default, configurable (2sec to 5 min)

Reporting rate: changed data for monitored events is reported without delay. Background data is reported at 15min rate (default, 2-60min)

Operating environment: -20C to 60C, 5-95% RH (non-condensing)

Battery: Primary lithium-thionyl chloride, 3.6V 7.5Ah

Battery lifetime: 5+ years with 30 min reporting interval at DRO (Battery lifetime reduced when operating at negative temperatures)

Enclosure: Polycarbonate, IP67, 120mm x 84mm x 55mm (including glands)

Weight: 280g

Power consumption: Idle: <10uA

Reporting interval: 30 mins (configurable)

Sampling Rate: 5 mins (configurable)

Alarm Sampling Rate: 5 mins (configurable)

Alarms: 2 x configurable High T alarms; 2 x configurable low temperature alarms

Compliance: R-NZ; AS/NZS4268:2017; LoRaWAN 1.0.2 AS923

Security: OWASP 2.0

Product life cycle: Expected minimum operational life 25 years. End of life, return to manufacturing based (Nelson, NZ) for recycling.

Pressure differential and Remote I/O: please enquire for further detail.

Ready to protect your bottom line and your peace of mind?

Discover how BenchMarker can give you peace of mind around the clock.

We’d love to hear about your special application.

Get in touch with our friendly and knowledgeable team today!